Exploring the Development of Self-Lubricating Engine Components

betbhai9 whatsapp number, radhe exchange register, my99 exch:Exploring the Development of Self-Lubricating Engine Components

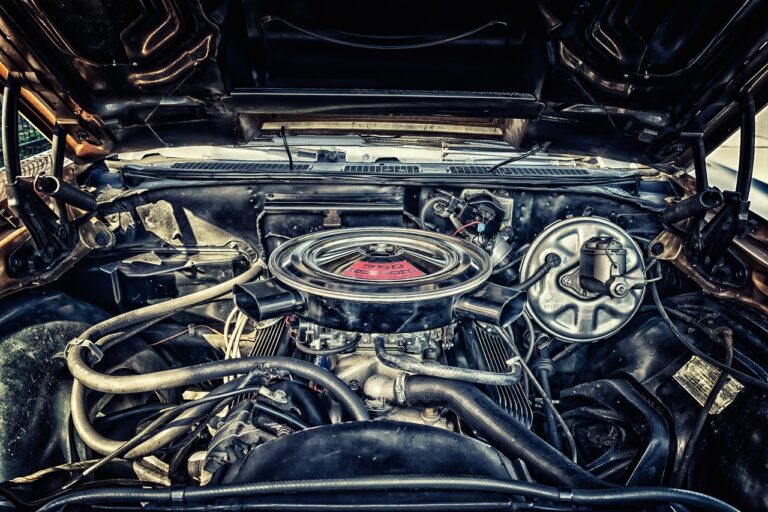

As technology continues to advance, the automotive industry is constantly seeking ways to improve engine efficiency and performance. One area of focus in recent years has been the development of self-lubricating engine components. These innovative parts have the potential to revolutionize the way engines operate, providing benefits such as reduced friction, improved fuel efficiency, and increased lifespan.

Self-lubricating engine components are designed to minimize the need for traditional lubrication methods such as oil changes and maintenance. By incorporating materials that have self-lubricating properties, these components can function more efficiently and effectively without the need for constant monitoring and upkeep.

One of the key materials that manufacturers are exploring for self-lubricating engine components is graphene. Graphene is a two-dimensional material that is incredibly strong and lightweight, making it an ideal candidate for use in engine parts. By integrating graphene into components such as pistons, bearings, and cylinder liners, engineers hope to create engine parts that can operate smoothly and efficiently without the need for regular lubrication.

In addition to graphene, other materials such as molybdenum disulfide and tungsten disulfide are also being studied for their self-lubricating properties. These materials can help reduce friction and wear on engine components, leading to improved performance and longevity.

Furthermore, advancements in nanotechnology are enabling researchers to create nanocomposite materials that exhibit self-lubricating properties. By combining nanoparticles with traditional materials, engineers can develop engine components that are more durable and efficient than ever before.

The development of self-lubricating engine components is still in its early stages, but researchers are optimistic about the potential impact that these innovations could have on the automotive industry. By reducing the need for regular maintenance and improving engine efficiency, self-lubricating components have the potential to revolutionize the way engines are designed and manufactured.

With ongoing research and development in this field, we can expect to see more self-lubricating engine components entering the market in the coming years. These advancements will not only benefit consumers by improving vehicle performance and reliability but also have a positive impact on the environment by reducing the consumption of lubricants and oils.

In conclusion, the development of self-lubricating engine components represents an exciting opportunity to enhance engine efficiency and performance. By exploring new materials and technologies, engineers are pushing the boundaries of what is possible in the automotive industry. As these innovations continue to evolve, we can expect to see significant improvements in engine design and functionality in the near future.

**Heading 1: The Benefits of Self-Lubricating Engine Components**

Self-lubricating engine components offer a range of benefits that can improve engine performance and longevity. By reducing friction and wear on critical parts, these components can enhance fuel efficiency and reduce the need for maintenance. Additionally, self-lubricating materials can help minimize heat buildup in the engine, leading to improved overall performance.

**Heading 2: The Role of Graphene in Self-Lubricating Components**

Graphene is a promising material for use in self-lubricating engine components due to its exceptional strength and lubricity. By incorporating graphene into pistons, bearings, and other parts, engineers can create components that operate more smoothly and efficiently. As research continues, we can expect to see more applications of graphene in engine design.

**Heading 3: Nanotechnology and Self-Lubricating Materials**

Advancements in nanotechnology are driving the development of self-lubricating materials that can enhance engine performance. By using nanoparticles to create nanocomposites, engineers can design components that exhibit superior lubrication and wear resistance. These innovations have the potential to transform the way engines are built and maintained.

**Heading 4: The Future of Self-Lubricating Engine Components**

The future of self-lubricating engine components looks bright, with ongoing research and development leading to new breakthroughs in materials and design. As automotive manufacturers continue to prioritize efficiency and sustainability, we can expect to see more self-lubricating components entering the market. These innovations will not only benefit consumers but also contribute to a greener, more sustainable automotive industry.

**Heading 5: Challenges and Opportunities**

While the development of self-lubricating engine components presents exciting opportunities, there are also challenges that must be overcome. Researchers and engineers must address issues such as material compatibility, cost-effectiveness, and scalability to ensure that self-lubricating components are viable for mass production. By tackling these challenges head-on, the automotive industry can realize the full potential of self-lubricating technology.

**Heading 6: Conclusion**

In conclusion, the development of self-lubricating engine components holds tremendous promise for the automotive industry. By leveraging advanced materials and technologies, engineers can create components that are more efficient, reliable, and sustainable. As research continues to push the boundaries of what is possible, we can look forward to a future where self-lubricating engine components are the norm rather than the exception.

**FAQs**

**Q: Are self-lubricating engine components available for purchase?**

A: While self-lubricating engine components are still in the early stages of development, some manufacturers are beginning to explore the use of these innovative materials in their products. As research progresses, we can expect to see more self-lubricating components entering the market in the near future.

**Q: How do self-lubricating engine components improve performance?**

A: Self-lubricating engine components reduce friction and wear on critical parts, leading to improved performance and efficiency. By minimizing the need for traditional lubrication methods, these components can enhance fuel efficiency and extend the lifespan of the engine.

**Q: Are self-lubricating engine components environmentally friendly?**

A: Yes, self-lubricating engine components can have a positive impact on the environment by reducing the consumption of lubricants and oils. By minimizing the need for regular maintenance and oil changes, these components help reduce waste and conserve resources.

**Q: What are the challenges in developing self-lubricating engine components?**

A: Some of the challenges in developing self-lubricating engine components include material compatibility, cost-effectiveness, and scalability. Researchers and engineers must address these issues to ensure that self-lubricating technology can be widely adopted in the automotive industry.